Stable and reliable gas chromatography plat

GC-501 series gas chromatographs have undergone professional reliability verification, according to GB/T11606-2007 "Environmental Test Methods for Analytical Instruments" in the third category of industrial process instruments, T/CIS 03002.1-2020 "Reliability Enhancement Test Methods for Electrical Systems of Scientific Instruments and Equipment" T/CIS 03001.1-2020 "Mean Time Between Failure (MTBF) Verification Method for Reliability of the Entire Machine" and other standards. The whole machine passes the thermal test, reliability enhancement test, comprehensive stress reliability rapid verification test, safety test, electromagnetic compatibility test, MTBF test, which guarantees the instrument to operate in a long term, stable and reliable way!

Accurate and excellent instrument performance

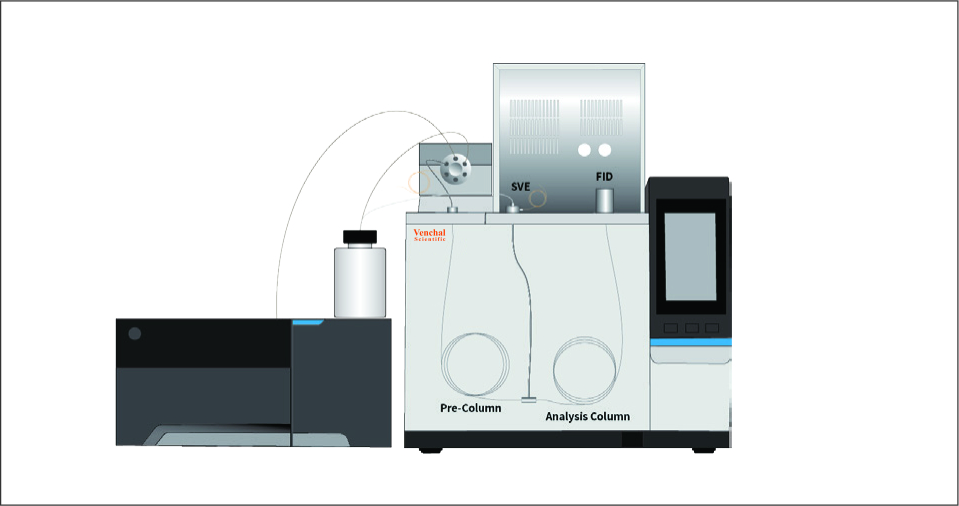

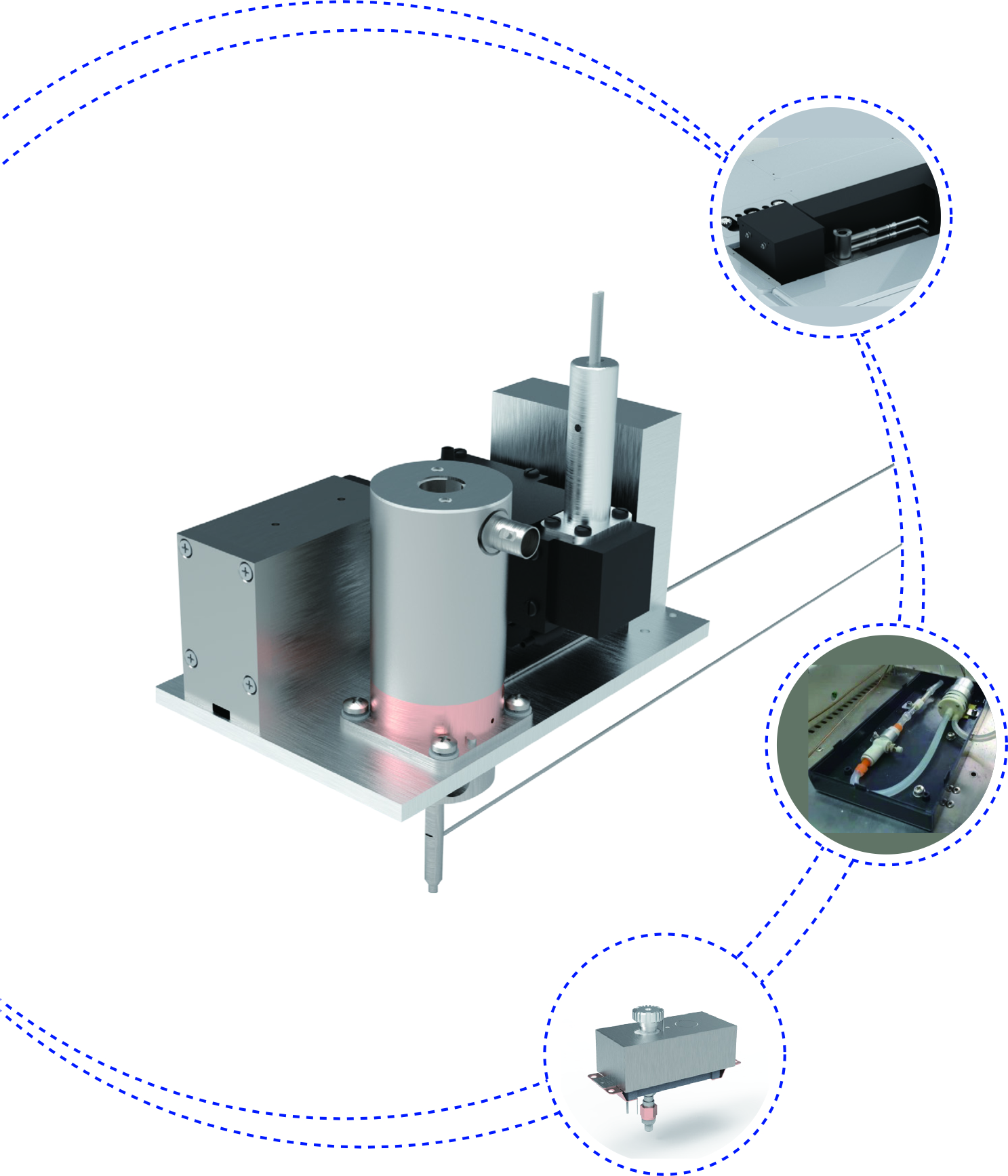

Large Volume Injection Technology (LVI)

- Maximum volume injection exceeding 500 μL

- Accurate time control and EPC system ensure sample repeatability

- Professional analysis techniques for special industries

Second Column Box

- Special molecular sieve column box for analysis of special gases such as refinery gas, capable of independent temperature control

- 50-350°C controllable, capable of executing independent chromatographic column aging program

High Precision EPC System

- EPC control accuracy ≤ 0.001psi (some models have it)

- Integrated EPC system

- Multiple types of EPC modules to meet the needs of users in various application scenarios

Capillary Flow Technology

- Special connection process to achieve small dead volume

- Surface Silanization Treatment of CVD Process

- Realizable Airflow Full 2D GCXGC Analysis Method

- Realizable center-cutting method for analyzing special substances in complex matrices

- Achieve the analysis of trace impurities in high-purity gases

Rapid Heating and Cooling System

- The fastest heating rate : 120°C/min

- Cooling time: from 450°C to 50°C within 4.0 min (room temperature)

- Program heating repeatability better than 0.5% (some models are better than 0.1%)

High-Performance Analysis System

- Qualitative repeatability ≤ 0.008% or 0.0008 min

- Quantitative repeatability ≤ 1%

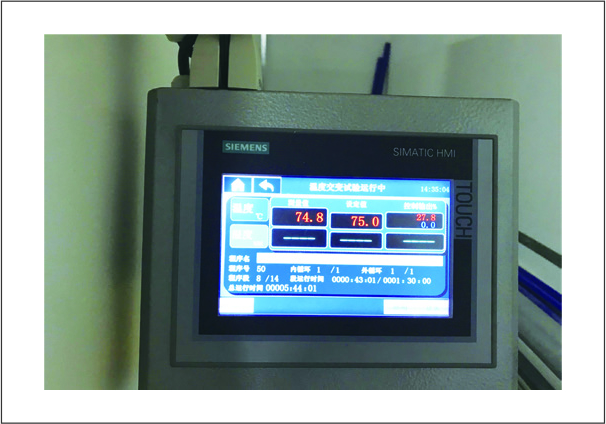

Intelligent and superior software control

Based on the electrical control module developed by the Linux system, the whole platform is accessed between the software and the host through the MQTT protocol, forming the mode of multi-terminal monitoring and controlling the instrument, which provides a solution for remote control and remote monitoring. It can realize the whole control the equipment through the chromatographic display.

Intelligent and Interconnected Gas Chromatograph Platform

- Control multiple gas chromatographs with one cell phone

- Access to the Internet to view instrument information at any time

- Instrument control via remote operation

- Edit GC methods without the need for a chromatography workstation.

- Check instrument status and sample runs at any time

Professional and Considerate Expert System

- Analyze instrument stability under current conditions with big data.

- Evaluate the detector performance of your gas chromatograph at any time

- Q&A-based instrument maintenance tests.

Intelligent interconnected workstation system

Multiple terminal workstation options to meet the differences in user usage habits

GCOS series workstations

- Implement real-time monitoring of instruments and processing of analytical data

- Guided operational logic minimizes user learning costs

- The selection of analytical flow paths allows one instrument to perform multiple sample analyses

- Compliance with national GMP requirements

Clarity series workstations

- Satisfy users' use of previous instrument workstations

- Able to connect various front-end and back-end instruments for chromatography to achieve workgroup operation

- Compliance with national GMP requirements

- A User-friendly, universal interface allows you to access advanced software features, including method switching and flow rate calculations.

- Share analysis results across the platform.

- Intelligent judgment of instrument consumable usage.

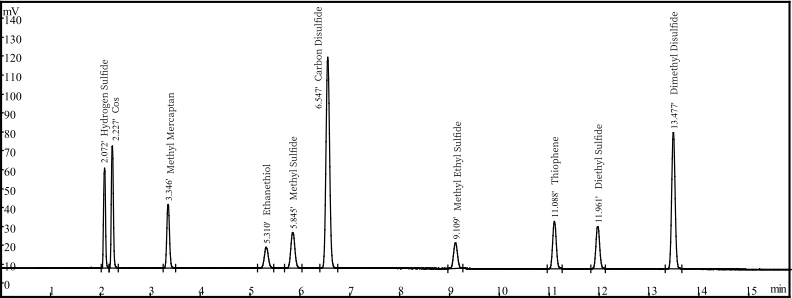

Unique small cold atomic fluorescence detector

Combining years of experience in chromatographic and spectral research and development, we have developed a unique small cold atomic fluorescence pump detector that can installed on laboratory gas chromatographs.

Patent No.: ZL 2019 2 1771945.8

Optimize the high-temperature cracking device to shield the interference of electric heating on the signal.

Patent No.: ZL 2022 2 2247701.8

Multidetector Expansion

Along with installing AFD, other detectors (FID, ECD, TCD, FPD, TSD, etc.) can also be installed. Use the least amount of equipment to make more samples and improve instrument efficiency.

Unique Optical System

- Ultra-high instrument sensitivity (combined with purge and capture) 0.07pg of methyl mercury and 0.09pg of ethyl mercury

- A minimum fluorescence detector with a size of 1/40 of the laboratory fluorescence spectrum

Active Exhaust Capture System

The mercury vapor passing through the detector is finally captured by a gold wire adsorption tube to ensure its capture efficiency, protect user health and safety, and reduce pollution to the atmospheric environment.Special injection port.

Special Injection Port

- Minimize injection dead volume and significantly reduce chromatographic peak broadening

- Preventing the adsorption effect of glass liner on ethyl mercury

Fully Applicable

- HJ 977-2018 "Water quality - Determination of alkyl mercury - Purge trap/gas chromatography cold atomic fluorescence spectrometry"

- HJ 1269-2022 "Determination of Methylmercury and Ethylmercury in Soil and Sediments"

Capillary Chromatography Column

- Higher chromatographic column efficiency

- Faster separation speed

- Higher sensitivity

- Chromatographic columns can be used for other application detection

Purge and Trap Gas Chromatography Platform

In addition to alkyl mercury analysis, multiple methods can be applied simultaneously to achieve one machine with multiple functions and improve instrument efficiency.

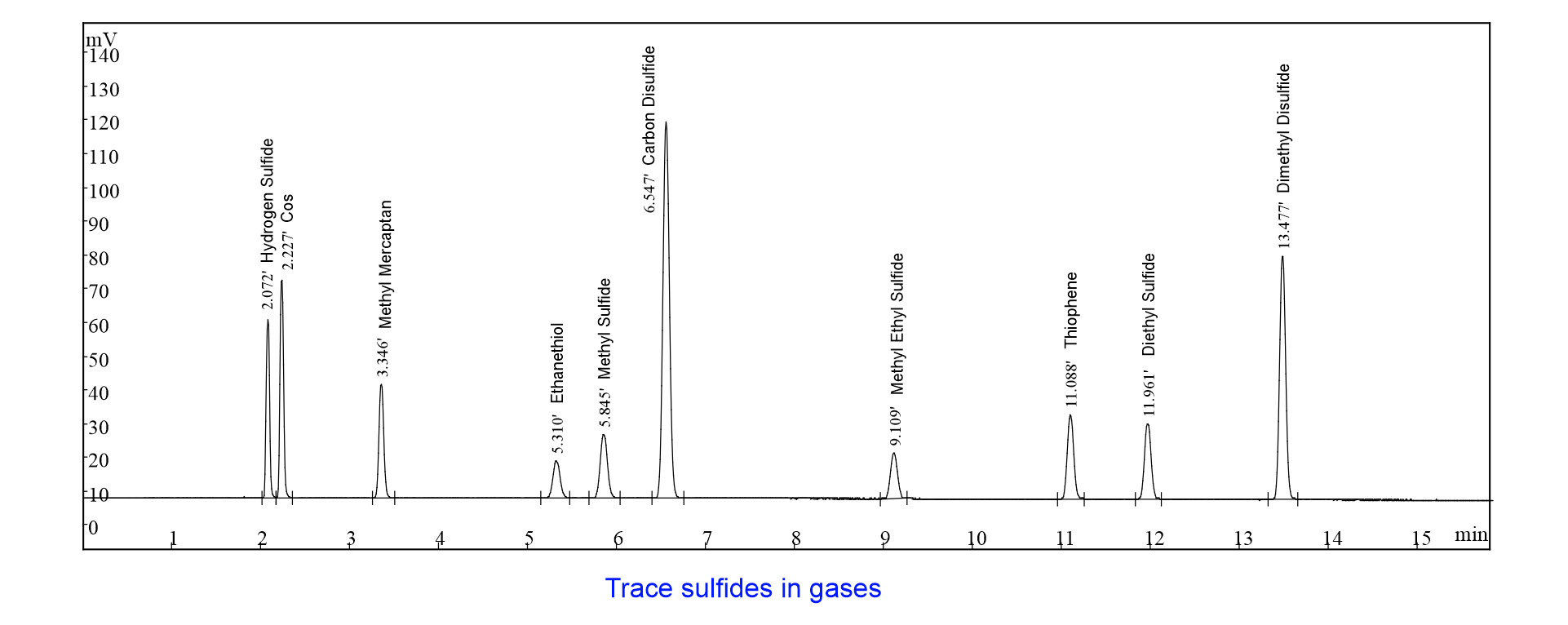

Application spectrum of Gas Chromatography

HS-600 Headspace Sampler

- Arrange the heating position matrix of the sample box in Zone A, and the heating temperature is uniform. Two separate heating zones of 10 and 2 positions, controlled separately;

- Optional B-zone sample box, arranged in a heating position matrix, capable of testing samples up to 24 positions;

- The sample transmission pipeline and quantitative ring adopt a high inert deactivation pipeline, which is free of residues and cross-contamination;

- The combination of a six-way valve and a quantitative ring minimizes dead volume and ensures injection accuracy;

- By using the classic positive pressure sampling method, liquid or solid samples can be measured with high detection sensitivity;

- The six-way valve is driven by a motor and does not require external driving gas, making it safe and convenient to use;

- Integrated design, compact overall structure; Quick start button, easy to operate and convenient;

- Equipped with an RS232 interface, it can communicate with the workstation, and the chromatography software is integrated for control. Various parameters can be set on the workstation.

HS-800 Headspace Sampler

- Automatic blowing and leak detection functions for the injection needle after injection;

- Mechanical arm type automatic sampler;

- Using a 12-position heating furnace, precise temperature control is carried out for each sample throughout the entire equilibrium time;

- Automatic sample overlapping heating method, which can accommodate 12 sample bottles while maintaining a constant temperature for each sample bottle;

- Using valve and quantitative tube injection methods. Standard fully electronic gas circuit for pressure control of the headspace bottle;

- Chemical inert sample flow path; Fully automatic purging of samples and vent pipelines during analysis intervals;

- Deactivated stainless steel injection probe;

- Flexible setting of injection quantitative volume range: 0-5ml;

- Equipped with an RS232 interface, it can communicate with the workstation, and the chromatography software is integrated for control. Various parameters can be set on the workstation.

APT-100S Fully Automatic Special Purging and Trapping Instrument

- In situ blowing method using headspace method in the bottle, with a sample injection volume of 25ml or more, suitable for sample bottles of 40ml/60ml;

- Three-channel capture and desorption module, which can simultaneously capture three or more samples;

- The external gas phase provides analytical gas, stable testing, and a stable baseline;

- The thermal desorption system adopts a high-power heating system with a heating insulation design, and the thermal desorption temperature is uniform. Dry cleaning process, argon gas back blowing trap at high temperature to avoid cross-contamination;

- Pipeline liquid inlet detection to prevent water vapor from entering the Tenax tube and chromatographic column.

ALS-500 liquid automatic sampler

The latest generation of automatic samples independently developed by BFRL has a beautiful appearance, small size, lightweight, convenient installation, strong universality, and adheres to excellent and reliable sampling technology. It can provide automatic gas chromatography analysis of up to 160 samples without interruption or monitoring.

- Implement multi-port full reverse control function to improve user applicability efficiency;

- Intelligent operation and intelligent prompts for user input;

- High stability, real-time encoder feedback comparison, and more stable instrument operation;

- The high degree of automation, unmanned, 24-hour uninterrupted work;

- The sample disk adopts an absolute position encoder to compensate for accumulated errors during operation;

- Adopting precision motor drive, providing multiple driving speeds, stable injection speed, and precise injection quantification;

- Safe error verification, where the system verifies data to ensure safer instrument operation;

- Supports dual tower injection, with high-time reproducibility for synchronous injection;

- Equipped with barcode scanning sample function and sample temperature control function, meeting the diverse needs of users.

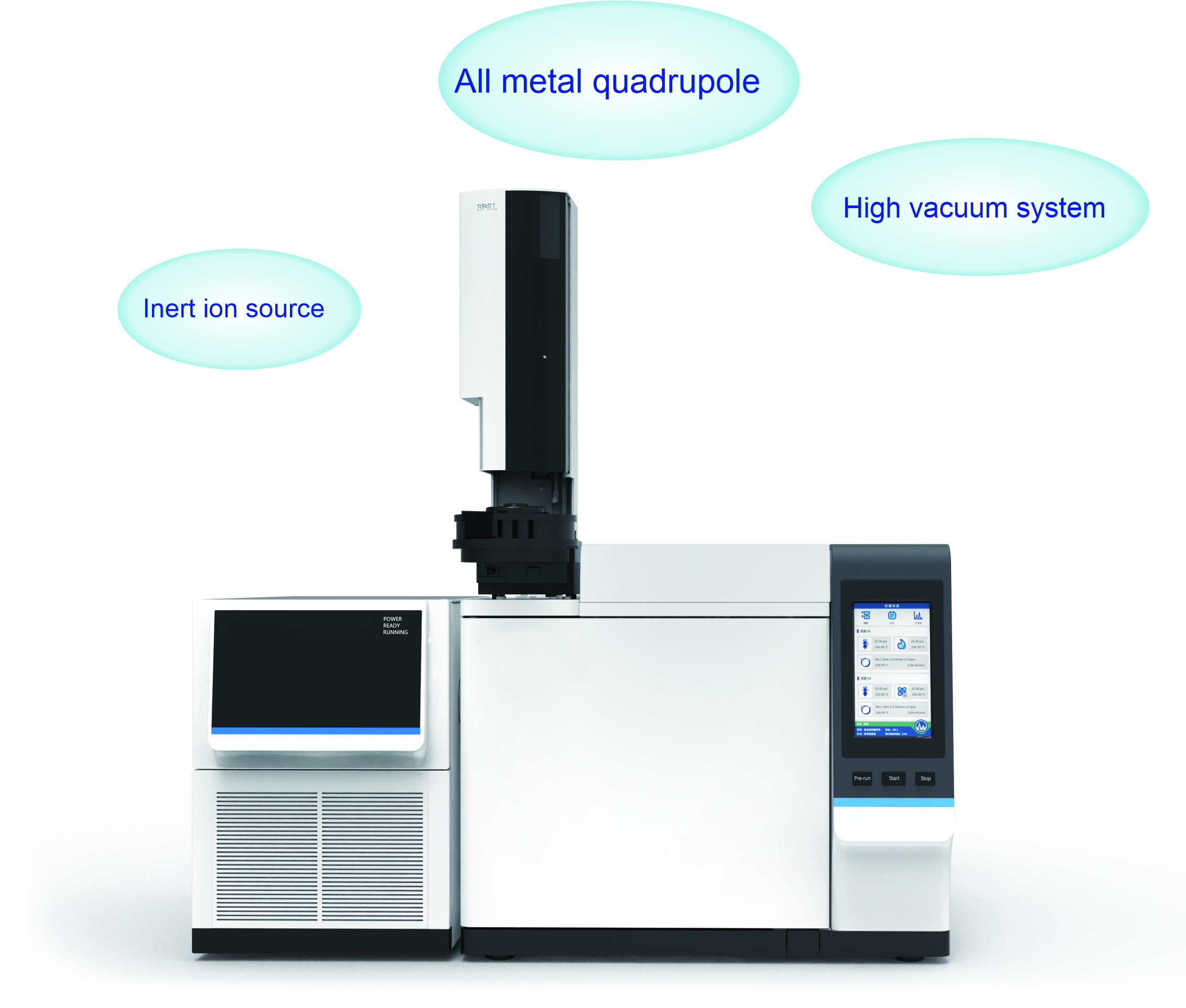

Gas chromatography-mass spectrometry platform

Inert Ion Source

- An inert ceramic ion source ensures that analytical substances will not adsorb on the ion source during long-term use, extending service life

- Dual filament design, alternating use to extend filament replacement time

- Visual judgment of filament working status through the filament observation port

All Metal Quadrupole

- High-precision all-metal quadrupole equipped with pre-quadrupole

- Pre-quadrupole disassembly for cleaning to avoid contamination of

the main quadrupole

- No temperature control is required to ensure quality stability indicators

High Vacuum System

- Optimizing ion energy technology Front stage pump,pumping speed

≥ 4m 3/h

- High-performance turbomolecular pump, pumping speed ≥ 250L/s

- Chromatographic column flow rate 5ml/min